Automated Stress Testing

About Resene Paints

Resene Paints is a manufacturing firm based in New Zealand. They provide high-quality paints, wall coverings, construction materials and an assortment of other supplies for home design and maintenance.

The Problem

Resene provides customers insulation nails and glues that are used to secure insulation blocks. To ensure maximum hold, these nails and glues need to be thoroughly tested for product integrity under a variety of conditions. Specific conditions that need to be tested for each of these products include performance under physical strain, performance under varied temperatures, and break point determination.

One of these tests is referred to stress testing. This is a process to determine the breaking point of a material under a load. This load is physical strain applied by the machinery, and is often studied in both the shear (i.e. cross-sectional) and tensile (i.e. length-wise) directions.

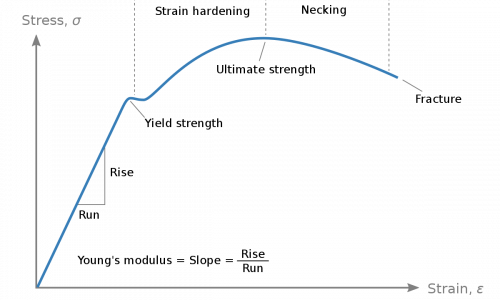

The figure below is an example of a typical stress-strain curve observed during stress testing. The yield strength refers to the load at which the material starts to display plastic behaviour; i.e. when the material begins to deform beyond recovery. The ultimate strength indicates the point at which the material begins “necking”, similar to how a rubber band becomes thinner as it is stretched. Finally, fracture indicates the load point at which the sample finally breaks. Throughout this whole process, its common practice to collect temperature data and sample thickness measurements relative to the load applied.

Another step to this analysis is to study the material as the load is reduced back down to zero, while collecting all of the data points mentioned above in the process. For example, researchers typically want to know how the deformation of the material is affected as load is reduced. Back to the rubber band example; will the rubber band stay elongated and thin (plastic deformation)? Will it return to its original length and thickness (elastic deformation)? These are the questions that stress tests and the related machinery can answer.

An example of stress testing machinery can be seen below:

Stress testing requires specialized equipment that is often very costly. External testing also slows down research and development due to scheduling and the availability of shared resources at the agency. In the case of Resene, there was also the challenge of accessing and managing historical data of prior tests for more robust analysis.

Considering the additional factor of the time required to transport physical samples to and from the testing agency, Resene found themselves bogged down with an R & D pipeline that was significantly longer than necessary. Product development at Resene depended heavily on rapid testing. Due to their high testing volume, this solution also needed to be implemented at reasonable cost. Here’s how we made that happen at T4tech.

The Solution

T4tech designed and delivered a custom, affordable testing rig to meet the operational needs at Resene and enable them to conduct their own in house testing and analysis of results. For each product and iteration of testing, this solution was able to capture the following data for Resene:

Load

The testing rig was designed to exert an incrementally increasing load on the sample until the breaking point. This allowed the user to determine exactly how much force could be applied before the sample broke (or deformed beyond recovery). If the sample was not pushed to the breaking point, the machinery was also able to de-load the sample to study its deformation behavior (i.e. plastic or elastic deformation).

Imagery of substrate

The rig was also able to capture imagery of the sample as load increased. With a high frame, this allowed users to visually study the sample, and observe cracks and deformations under stress and varied conditions. From this, researchers could pin point exactly where breakage most often occurred in their testing samples for continuous product improvement.

Laser measurement of substrate deformation

Measuring the deformation of the sample is vital for understanding maximum loads that can safely be applied. For metals in particular, this deformation is nearly imperceptible to the human eye fractions of a second before sample failure. That’s why T4tech designed a laser measurement system to quantify deformation with ultra-high accuracy, giving researchers another data point with which to evaluate the behavior of their samples.

Thermal imaging

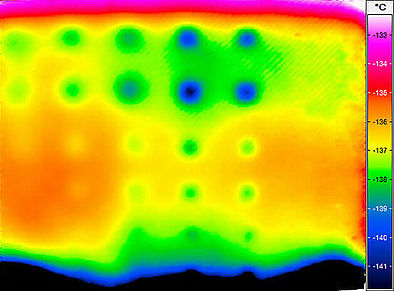

Material testing for real-world applications requires testing under real-world conditions. For stress testing, accurate temperature data is one of the most important conditions to monitor. For this reason, T4tech is working on a testing rig to capture and deliver high-resolution thermal imagery of the sample. Doing so will allow Resene to better understand the behavior of their materials under varied temperatures, while enabling a clear view of sample weaknesses.

All of the data above is made available with timestamp annotations. This allowed Resene to conduct post-experiment analysis to study weakness, breakdown points, and common patterns by studying the test results frame-by-frame.

Another solution sought by Resene was related to insulation testing. The company needed a way to ensure their insulation product offerings were up to customer standards. But as with the stress testing unit, Resene did not have in-house options available. Having to rely on external testing providers once again presented delays in product development and needless cost to operations.

T4tech solved this for Resene by delivering a custom insulation testing unit. Here, we designed a controlled thermal chamber with a cold and warm end. Doing so allowed Resene to conduct affordable in-house insulation testing by measuring the heat loss using thermal cameras at either end of the chamber. This tool dramatically sped up research and development for reason by enabling in-house testing, with the added benefit of reducing the cost required to conduct these tests.

T4tech provides smart and accessible technology to local businesses and allow them to be competitive in their markets and deliver high quality products. Get in touch with us today to find out how we can help your business excel in technology.