Resene Paints: Automated Stress‑Testing System

The Challenge

Resene Paints, New Zealand’s biggest manufacturer of paints and building supplies, needed a faster, more affordable way to test the strength and durability of the substrates, glues, and insulation products it offers. Traditionally, these stress tests were performed by external laboratories—a process that introduced long wait times, high costs, and fragmented data records. Each round of testing could take weeks, slowing the pace of research and development.

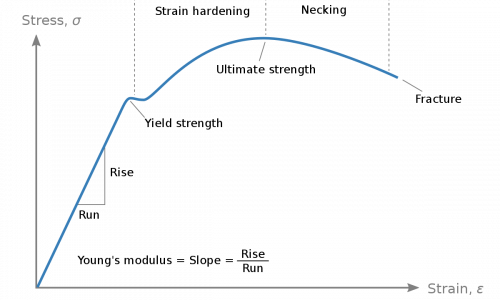

Stress testing applies controlled force—whether tensile, shear, or compressive—until a material yields or fractures. By capturing how and when failure occurs, engineers gain the hard data they need to refine formulations and validate quality. Resene wanted that capability in‑house, so they could iterate quickly on new products while grounding every decision in sound science.

T4tech’s Solution

T4tech partnered with Resene to design and build a fully automated stress‑testing rig that brings lab‑grade capabilities onto the factory floor. Handling the entire project end‑to‑end—from mechanical integration and electronics through firmware and data‑analysis software—T4tech delivered a turnkey system that:

Applies precisely controlled loads using a motor‑driven actuator and precision load cells with instrumentation amplifiers.

Measures micro‑level deformation via a laser displacement sensor.

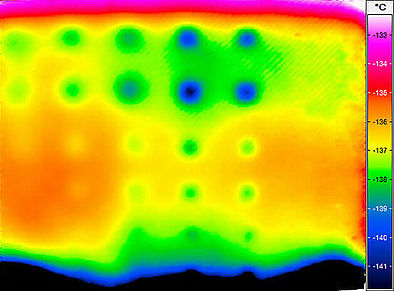

Captures high‑speed video and integrates an infra‑red camera for thermal profiling.

Houses samples in a custom temperature‑controlled chamber, enabling tests at user‑defined hot and cold extremes.

Logs every sensor reading in real time and auto‑generates stress–strain graphs and thermal plots for instant insight.

All this functionality is wrapped in an intuitive interface that lets technicians queue a test, walk away, and return to a complete, time‑synchronized data set—video frames, temperature maps, force curves, and more—ready for analysis.

Results

With their new in‑house rig, Resene can now:

Slash turnaround times from weeks to hours, dramatically accelerating R&D cycles.

Cut external lab costs, redirecting budget to product innovation.

Build a centralized archive of stress profiles and thermal data for every formulation, driving data‑informed decisions across teams.

The project’s success hinged on close collaboration. T4tech iterated prototypes alongside Resene engineers, tweaking load ranges, grip designs, and software dashboards until the system fit seamlessly into existing workflows.

Stress testing machinery:

Looking Ahead

The collaboration doesn’t end here. Planned upgrades include:

Hydraulic‑press expansion for higher‑capacity loading—ideal for larger or stronger substrates.

Automated experiment replay, where scripted sequences (force ramps, temperature cycles, dwell times) run hands‑free, ensuring perfect repeatability across tests.

By transforming a costly bottleneck into an on‑site competitive advantage, T4tech’s automated stress‑testing system empowers Resene Paints to innovate faster, validate with confidence, and keep pushing the boundaries of material performance.